Versatile joining with additional fastener

Head

Researcher

Funding period:

Start: 1. July 2019

Ende: 30. June 2027

Abstract

Due to increasing economic and ecological requirements, the trend

towards lightweight construction has become increasingly important in

recent years. A central aspect of this development are multi material

designs combining high-strength steels and aluminum components with

increased complexity and a high number of variations. For the assembly

and connection of components made of different materials, joining

processes are necessary that enable the joining of workpieces with

varying mechanical and geometrical properties. One approach is the use

of the forming and pre-hole-free joining process with self piercing

rivets, which is characterized by high resource and process efficiency.

However, due to the increasing demands on joining technology in regard

to materials and geometries, new processes and methods for the

production of versatile and tailored joints are necessary.

The aim of

the project is the development of a versatile self piercing riveting

process which is robust against deviations and process variations.

Therefore, two possible solution strategies are pursued, which

complement each other synergetically. The first approach contains the

description of an adaptive, linear process control for the investigation

of the transformability of used additional joining parts. This part of

the project is being worked on by the project partner at the LWF in

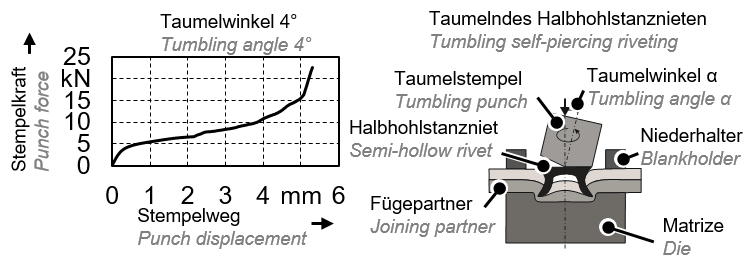

Paderborn (https://mb.uni-paderborn.de/lwf). The second solution

strategy, which is pursued at the LFT, includes the adaptation of the

tool kinematics to the joining process and a versatile in situ control

of the process parameters. An orbital forming process is used which is

adapted to the joining materials and geometries with regard to orbital

forming kinematics and process control, thus enabling tailored joints

with increased process robustness.

Research groups

Publications

2023

- , , , , , :

Numerical Investigation of the Influence of a Movable Die Base on Joint Formation in Semi-tubular Self-piercing Riveting

In: Materials Design and Applications IV, Springer Science and Business Media Deutschland GmbH, 2023, p. 137-149 (Advanced Structured Materials, Vol.168)

DOI: 10.1007/978-3-031-18130-6_10 - , , , , :

Innovative mechanical joining processes in versatile process chains - potentials, applications and selection procedures

Sheet Metal 2023 - 20th International Conference on Sheet Metal (Nürnberg, 2. April 2023 - 5. April 2023)

In: Materials Research Proceedings 2023

DOI: 10.21741/9781644902417-13 - , , , , , :

Mechanical joining of high-strength multi-material systems - trends and innovations

In: Mechanics & Industry 24 (2023), p. 1-20

ISSN: 2257-7777

DOI: 10.1051/meca/2023013 - , , :

Versatile self-piercing riveting with a tumbling superimposed punch

26th International ESAFORM Conference on Material Forming (Kraków, 19. April 2023 - 21. April 2023)

DOI: 10.21741/9781644902479-122 - , , , :

Combination of versatile self-piercing riveting processes

International Conference on Sheet Metal 2023 (Nuremberg, 2. April 2023 - 5. April 2023)

In: Materials Research Proceedings 2023

DOI: 10.21741/9781644902417-16

2022

- , , , :

Determining the properties of multi-range semi-tubular self-piercing riveted joints

In: Production Engineering (2022)

ISSN: 0944-6524

DOI: 10.1007/s11740-022-01105-2 - , , , , :

Joining of multi-material structures using a versatile self-piercing riveting process

In: Production Engineering (2022)

ISSN: 0944-6524

DOI: 10.1007/s11740-022-01151-w - , , , , , , , , , , , , , , :

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

In: Journal of Advanced Joining Processes (2022)

ISSN: 2666-3309

DOI: 10.1016/j.jajp.2022.100108 - , , , , , , , , , , , , , , , , , , , , , , , , :

Review on mechanical joining by plastic deformation

In: Journal of Advanced Joining Processes (2022)

ISSN: 2666-3309

DOI: 10.1016/j.jajp.2022.100113 - , , , , :

Pin Extrusion for Mechanical Joining from Orbital Formed Tailored Blanks with Local Material Pre-Distribution

In: Journal of Manufacturing and Materials Processing 6 (2022), p. 127

ISSN: 2504-4494

DOI: 10.3390/jmmp6060127 - , , , :

Geometric and mechanical joint characterization of conventionally and tumbled self-piercing riveting joints

In: Proceedings of the Institution of Mechanical Engineers Part L-Journal of Materials-Design and Applications (2022), p. 146442072211354

ISSN: 1464-4207

DOI: 10.1177/14644207221135400 - , :

Investigation of the influence of the tumbling angle on a tumbling self-piercing riveting process

In: Proceedings of the Institution of Mechanical Engineers Part L-Journal of Materials-Design and Applications (2022), p. 146442072210800

ISSN: 1464-4207

DOI: 10.1177/14644207221080068 - , :

Versatile tool design for a tumbling self-piercing riveting process

The 12th Tooling Conference & Exhibition, Tooling 2022 (Örebro, 25. April 2022 - 27. April 2022)

2021

- , , , , :

Inverse parameter identification of an anisotropic plasticity model for sheet metal

40th International Deep-Drawing Research Group Conference (IDDRG) (, ELECTR NETWORK)

In: INTERNATIONAL DEEP-DRAWING RESEARCH GROUP CONFERENCE (IDDRG 2021), BRISTOL: 2021

DOI: 10.1088/1757-899X/1157/1/012004 - , , :

Investigation of the influence of varying tumbling strategies on a tumbling self-piercing riveting process

In: Production Engineering (2021)

ISSN: 0944-6524

DOI: 10.1007/s11740-021-01099-3 - , :

Material characterisation methods for a tumbling self-piercing riveting process

24th International ESAFORM Conference on Material Forming, ESAFORM 2021 (, 14. April 2021 - 16. April 2021)

In: ESAFORM 2021 - 24th International Conference on Material Forming 2021

DOI: 10.25518/esaform21.398 - , :

Friction Characterisation for a Tumbling Self-Piercing Riveting Process

In: Key Engineering Materials 883 (2021), p. 27-34

ISSN: 1013-9826

DOI: 10.4028/www.scientific.net/KEM.883.27 - , :

Investigation of the Influence of the Tumbling Angle on a Tumbling Self-Piercing Riveting Process

2nd International Conference on Advanced Joining Processes AJP 2021

DOI: 10.1177/14644207221080068

2020

- , , , :

Test method for friction characterization of rivets

In: Defect and Diffusion Forum 404 DDF (2020), p. 132-137

ISSN: 1012-0386

DOI: 10.4028/www.scientific.net/DDF.404.132