Analysis of the influence of tribological properties on the deep drawing process of sheet metals after passing a drawbead

Head

Researcher

Funding period:

Start: 1. November 2018

Ende: 31. July 2021

Abstract

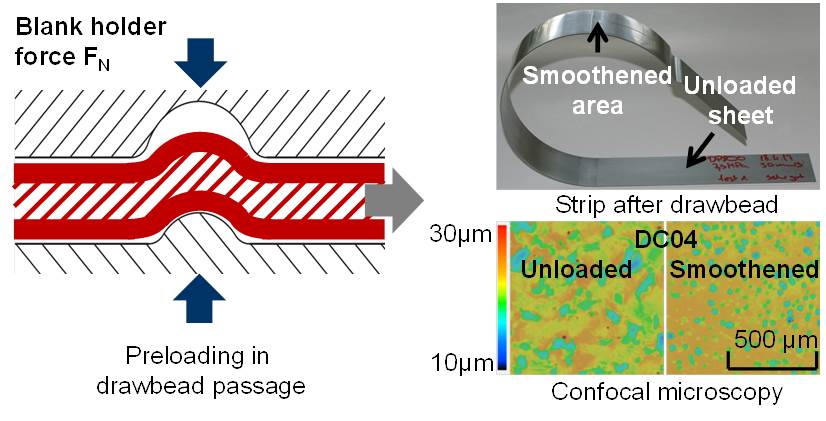

The project EFB 05 217 / AiF 20015N is dealing with the tribological system in a drawbead passage.

Recent studies (also provided in the project EFB 08/114)

have shown that material properties change significantly after a

drawbead. This can lead to a shift in process limits what is also due to

the influence of tribological properties. During the preloading in a

drawbead, visible changes in the surface itself area a result of higher

surface pressures in occurring in the drawbead. These effects, such as a

recognizable surface modification, are mostly unexplored at the moment.

The goal of this project is the fundamental analysis of the effects of

drawbeads on the tribological processes and to improve the understanding

of the use and operation of drawbeads for industrial use. These

investigations are associated with micro- and macroscopic

characterizations before and after passing a drawbead. The drawbead is

chosen by industrial standards and all experiments are conducted at the

Institute of Manufacturing Technology.

Shorter development cycles are a major challenge for small and medium size companies. Results of these experiments are expected to improve the numerical interpretation and will lead to cost savings, time advantages and therefore to competitive advantages. For the cost-effective fulfillment of various tasks in the forming technology, the virtual process design is suitable. Wrong simulations can lead to misconstructions. The results will be validated by the transfer to a deep-drawing process with drawbead in real size part. The participation of well-known companies in the project committee (PbA) is ensuring a practical benefit.

Tribological analysis after a drawbead passage

Research groups

Publications

2021

- , :

Analysis of the influence of tribological properties on the deep drawing process of sheet metals after passing a drawbead

(2021)

(anderer) - , , :

Comparison of different forming methods on deep drawing and springback behavior of high-strength aluminum alloys

40th International Deep-Drawing Research Group Conference (IDDRG) (ELECTR NETWORK)

In: INTERNATIONAL DEEP-DRAWING RESEARCH GROUP CONFERENCE (IDDRG 2021), BRISTOL: 2021

DOI: 10.1088/1757-899X/1157/1/012048 - , :

Analysis of Work Hardening and Tribological Changes After a Gap Controlled Drawbead Passage

ICTP (Columbus, Ohio, USA)

In: The Minerals, Metals & Materials Series. Springer, Cham. 2021

DOI: 10.1007/978-3-030-75381-8

2020

- , :

Influence of a drawbead passage in deep drawing processes on surface values and the tribological system

International Deep-Drawing Research Group (IDDRG 2020) (Seoul Korea)

DOI: 10.1088/1757-899X/967/1/012008